Discover our latest plastisol designed for Cr(VI)-free treatments

Discover our latest plastisol designed for Cr(VI)-free treatments

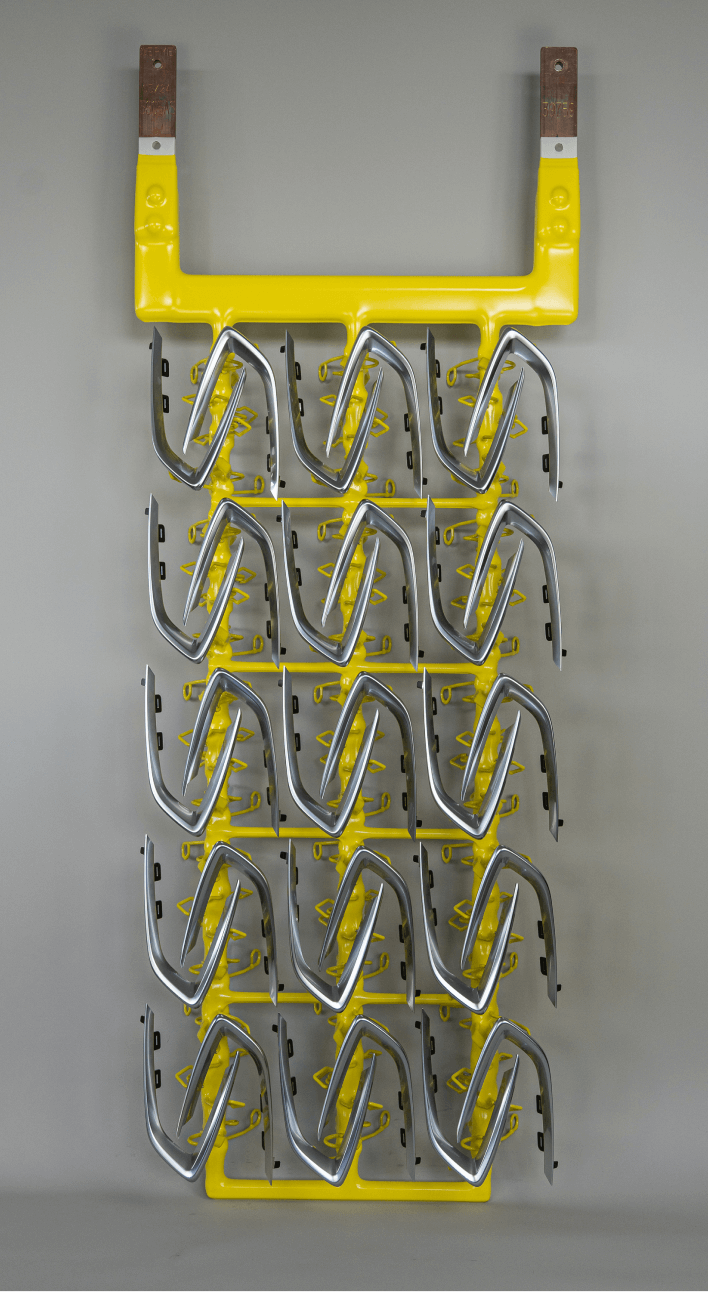

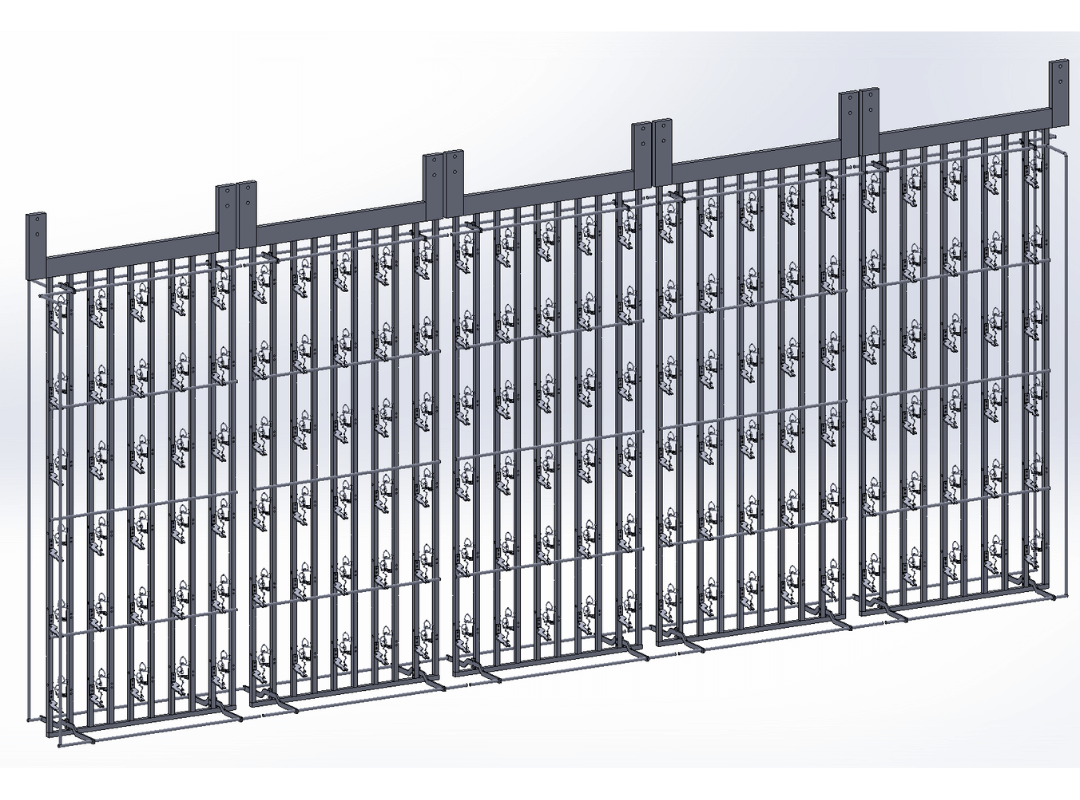

SERME specialises in the design and production of racks and jigs for surface treatment by electrolysis (electroplating).

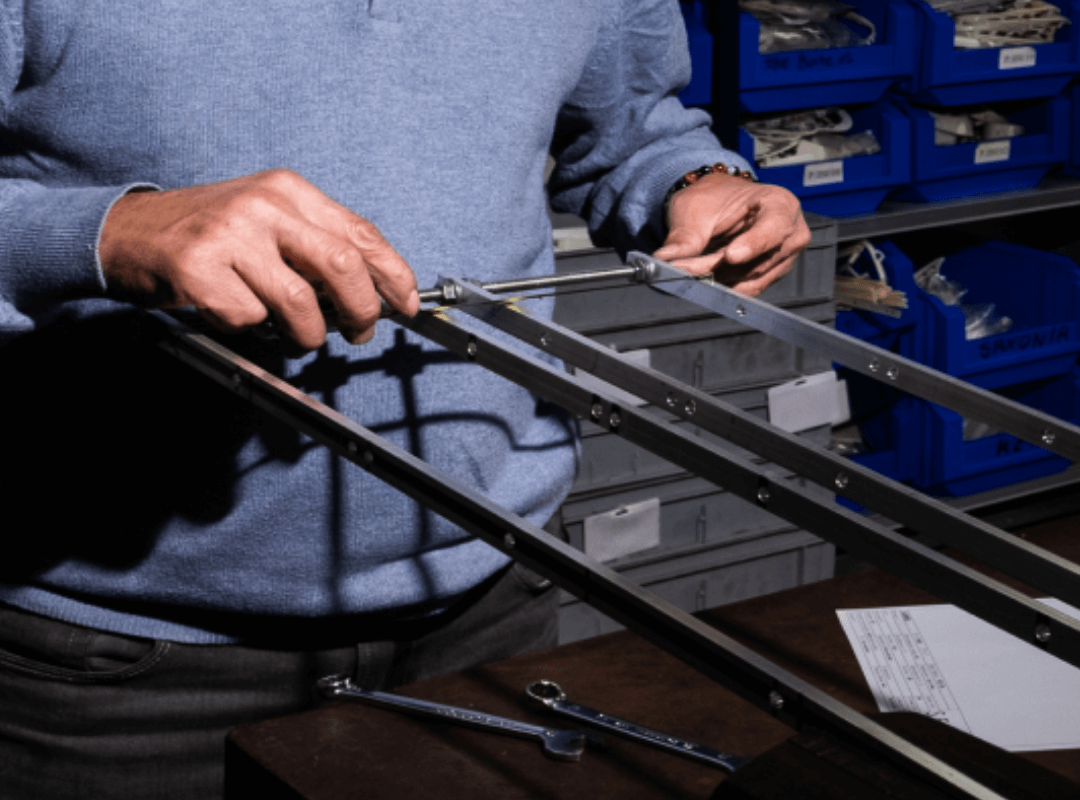

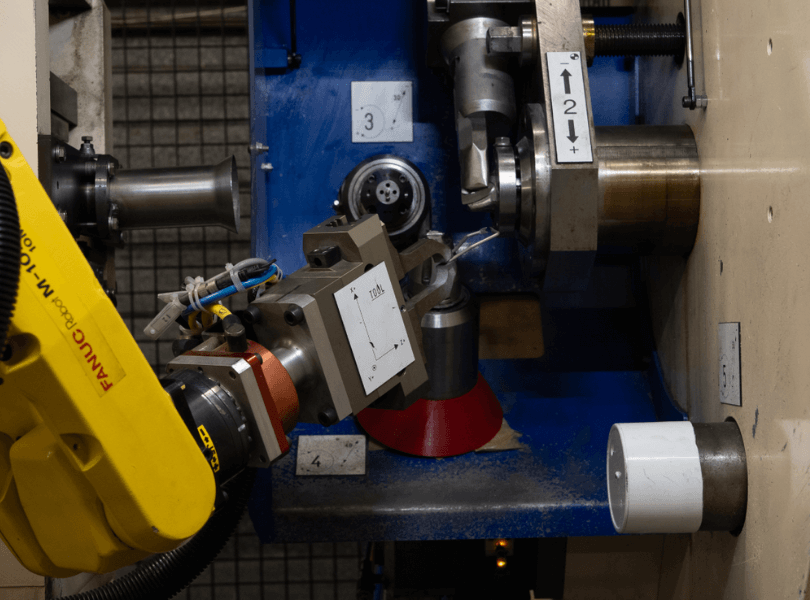

SERME is able to manufacture large quantities while meeting the shortest deadlines and the most demanding quality standards thanks to a 3,500 m² production unit, modern and efficient production tools and a team of around thirty people,

50 years of experience and know-how make SERME the partner of the most significant manufacturers and subcontractors in many industrial fields such as automobile, cosmetic, health care, household appliances, eyewear, or luxury leather goods.

In addition to its core business, SERME develops and uses different formulations of patented plastic coating processes, both for bespoke as well as for its own needs.

SERME pays particular attention to details for its products, in regard to methods and components used, in order to respect all human and environmental requirements.

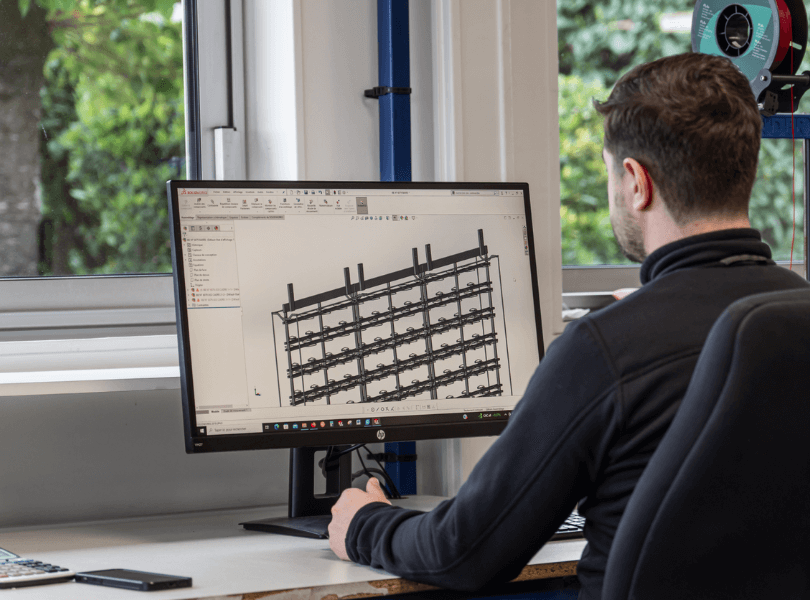

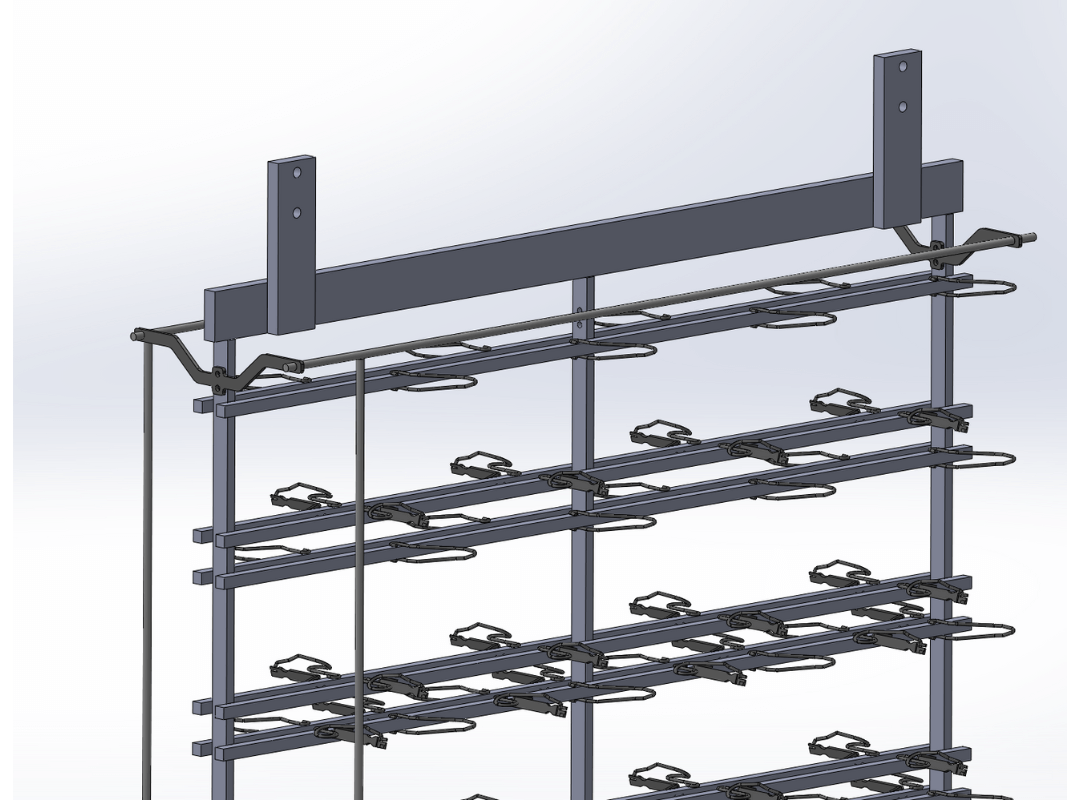

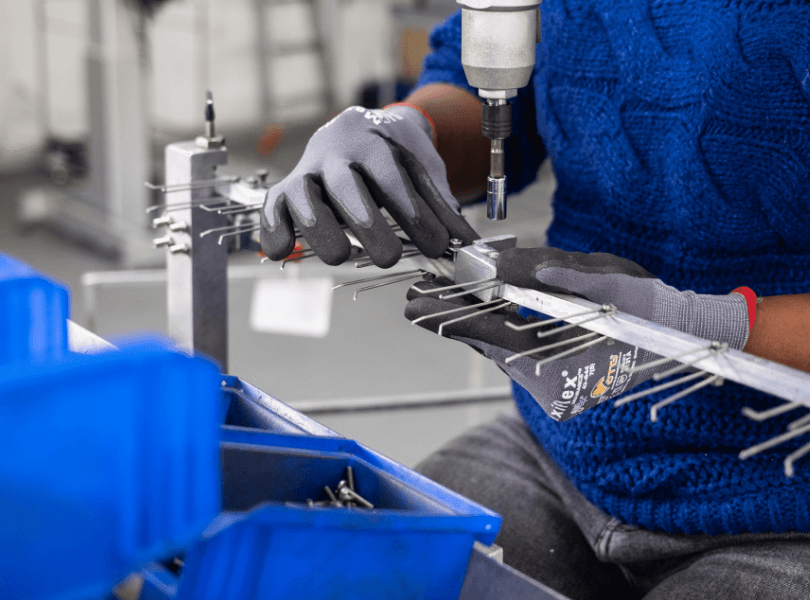

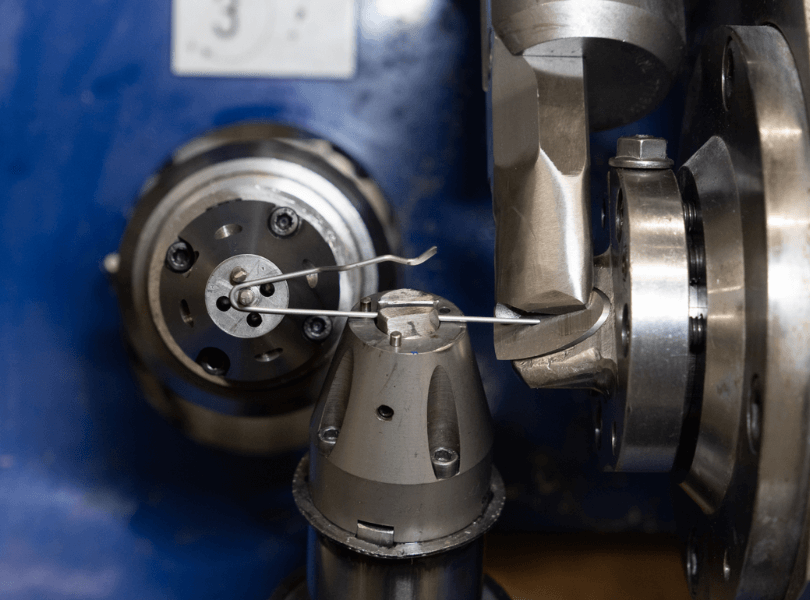

Before each production, a prototyping step is carried out to simulate th process of loading and unloading the parts, as well as the design of the contacting.

Serme uses 3D design tools to guarantee the best precision and a high level of repeatability. CAD allows excellent visualisation of the layout of parts, and of the contact hooks design during development phase.

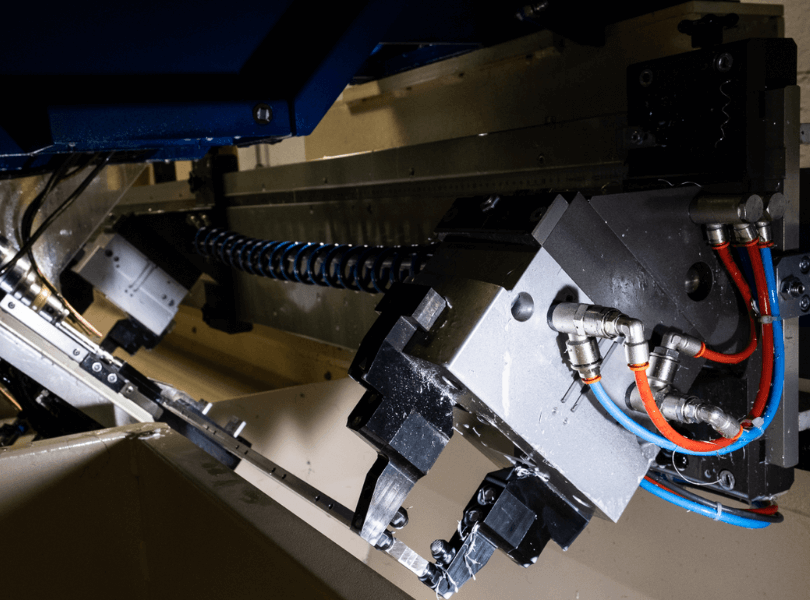

Thanks to a fleet of state-of-the-art manufacturing equipment and a team of qualified professionals, SERME guarantees productions that meet all requirements.

We can peel your racks. This is carried out with meticulous care and is adapted to each part.

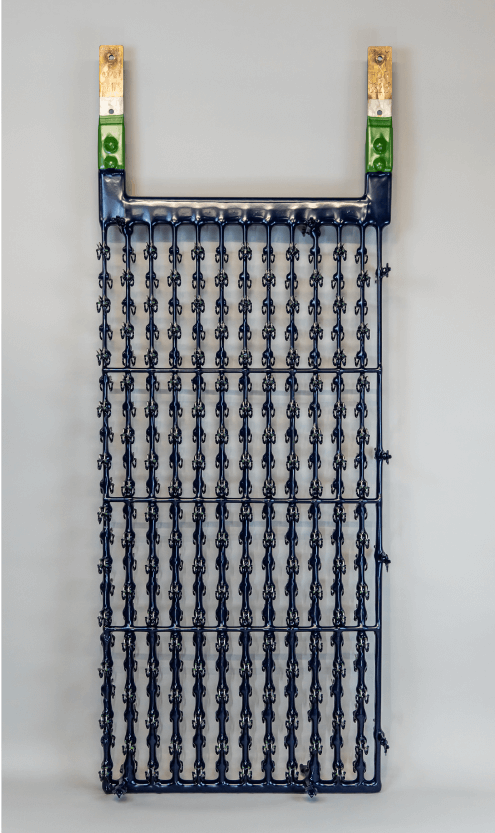

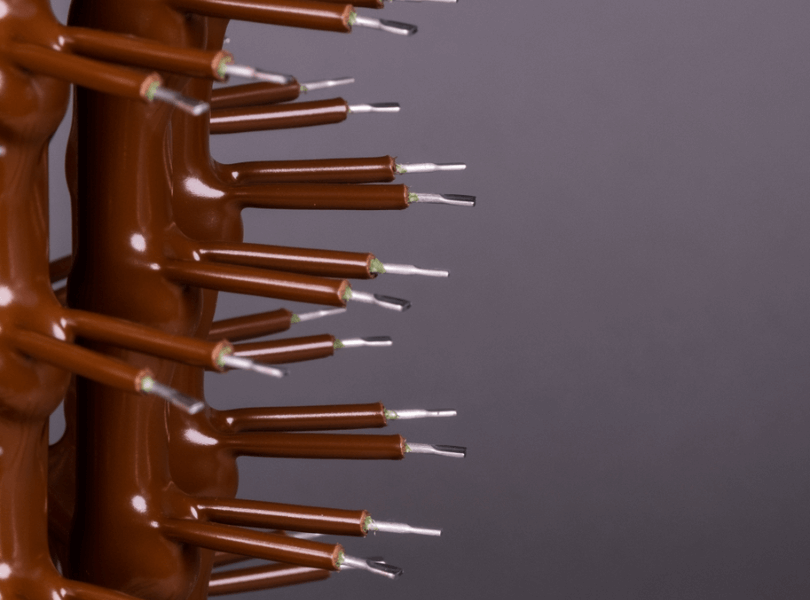

Over the years, SERME has developed multiple Plastisol formulations and patented plastic coating processes in order to meet constantly evolving technical and environmental requirements.

Flexible plastisol for first layer in the Dicoplast 2-layer process

Hard plastisol for the second layer in the Dicoplast 2-layer process, for electroplating of metal and plastic parts in ABS.

Extra hard plastisol for the second layer in the Dicoplast 2-layer process, suited for electroplating of metal and plastic parts in ABS, ABS PC, PP or PA.

Plastisol dedicated to Cr(VI)-free electroplating of plastic parts in ABS, ABS PC, PP or PA.

Thanks to its catalysis inhibitor complex, PLASTISOL 106 offers optimal protection against the risks of metallisation in Cr(VI)-free processes.

Designed to protect all electroplating racks, PLASTISOL 106 is particularly suitable and efficient for the treatment of plastic substrates in ABS, ABS PC, PP or PA

PLASTISOL 106 allows the use of chemistry without chrome VI and contains no PFAS, therefore it contributes to compliance with REACH regulations.

PLASTISOL 106 retains its flexibility and longevity thanks to the DICO PLAST 2-layer process

PLASTISOL 106 does not require any pre-treatment and can be integrated into existing plating processes.

Contact us for any inquiries or collaboration requests. Reach out to us via email or phone for prompt assistance and professional service.